Problem:

Facing a lack of historical data, operational constraints, and unpredictable environmental factors, Wolverine Terminals aimed for fuel supply optimization in a port in Canada.

Solution:

Partnering with MOSIMTEC, Wolverine Terminals developed a discrete-event simulation model in AnyLogic, which featured an Excel interface for scenario testing and port efficiency optimization.

Results:

- Validated throughput capacity for sustainable fuel distribution.

- Identified bottlenecks in fuel transfer and blending operations.

- Optimized port efficiency to ensure smooth vessel turnaround.

- Provided long-term usability, enabling Wolverine Terminals to run independent scenario analyses.

Introduction: navigating success in fuel supply optimization processes

Wolverine Terminals is a Canada-based company specializing in marine fuel solutions. With a focus on innovative logistics and infrastructure, Wolverine Terminals is committed to enhancing fuel supply chain efficiency in key port locations.

The company’s latest venture is establishing a marine fuel distribution operation in Prince Rupert, Canada. This is a major port that, despite its strategic importance, lacked dedicated marine fueling services until now.

Wolverine Terminals partnered with MOSIMTEC, a consulting company, to develop a discrete-event dynamic simulation that would help study the throughput capacity of this new marine fuel operation.

Problem: need for port efficiency optimization with no historic data to rely on

Wolverine Terminals sought to establish an efficient marine fuel operation in a complex and dynamic environment. The company aimed to stress-test the maximum volume throughput capability of the entire system. Additionally, it wanted to understand other system constraints, identify bottlenecks, and pinpoint opportunities for fuel supply optimization.

Key challenges of this ambitious project included:

- Lack of historical data: As a new operation, no prior throughput or performance data was available.

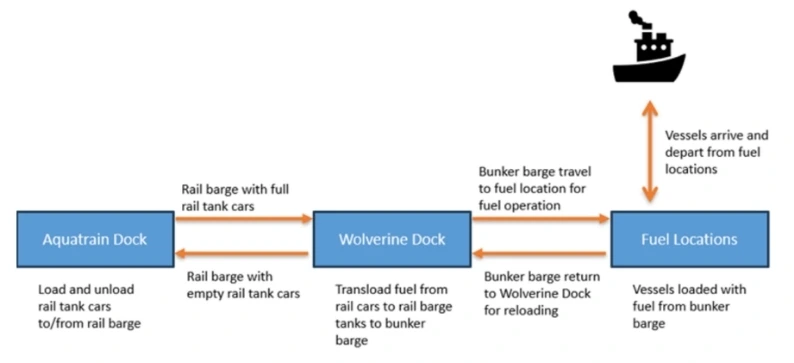

- Operational constraints: The patented barge system relied on multiple interdependent components, including rail logistics, fuel blending, and customer servicing.

- Environmental factors: Variables such as tidal cycles, seasonal daylight hours, and weather patterns significantly impacted the marine fueling service's operational feasibility.

- Limited berth time & customer demand variability: Vessel arrival times, service durations, and capacity constraints needed careful consideration.

- Tight project timeline: The simulation model had to be developed, validated, and analyzed within 2-3 weeks.

Solution: a discrete-event simulation model in AnyLogic

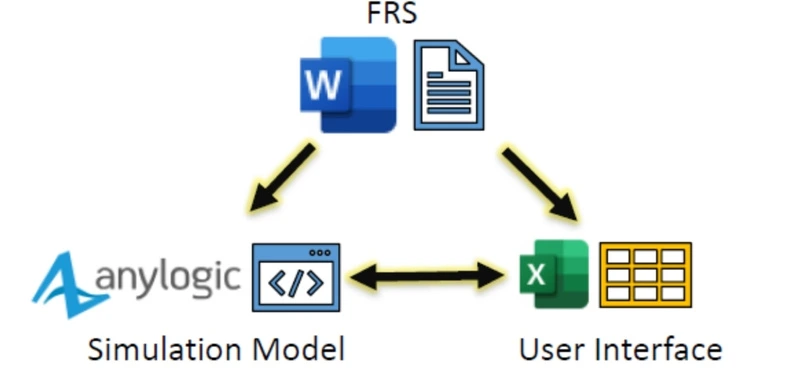

MOSIMTEC developed a discrete-event simulation model in AnyLogic, featuring an Excel-based user interface, which enabled Wolverine Terminals to conduct independent scenario testing. The model structure included:

- 154 configurable parameters, including barge attributes, fuel types, customer demand, and external factors (such as weather and tides).

- 21 unique time distributions, capturing variables such as customer berth durations, vessel arrival patterns, and seasonal disruptions.

To ensure the efficiency of simulation modeling, the following assumptions and justified simplifications were made:

- Simplified rail yard logic: To focus on fuel supply optimization, rail car availability was assumed to be constant.

- Zonal customer representation: Instead of tracking precise locations, customers were categorized into operational zones (A, B, C).

- Minimal animation: To prioritize performance metrics over visualization, the model emphasized statistical outputs and efficiency analytics.

The model was tested 100 times in different scenarios to see how input changes affected port efficiency and key performance indicators (KPIs). These indicators included:

- Total throughput capacity.

- Customer service levels.

- Asset utilization.

The Excel-based front end enabled Wolverine Terminals to modify inputs, run simulations, and analyze results independently, ensuring the long-term model’s usability beyond the project timeline.

Explore other successful projects with a focus on efficiency optimization of port and terminal operations using AnyLogic in our industry-specific case study section.

Results: validated throughput capacity assumptions for port efficiency optimization

The model confirmed that the infrastructure could meet expected demand levels while identifying potential improvements for port efficiency optimization. It also revealed key operational bottlenecks in the fuel transfer and blending process, enabling proactive adjustments. Moreover, Wolverine Terminals utilized the model to assess the return on investment (ROI) and optimize its resource allocation.

As Wolverine Terminals moves forward, the simulation model remains a valuable tool for refining strategies for fuel supply optimization and adapting to real-world operational dynamics.

The case study was presented by George Miller from MOSIMTEC at the AnyLogic Conference 2024.

The slides are available as a PDF.