Problem:

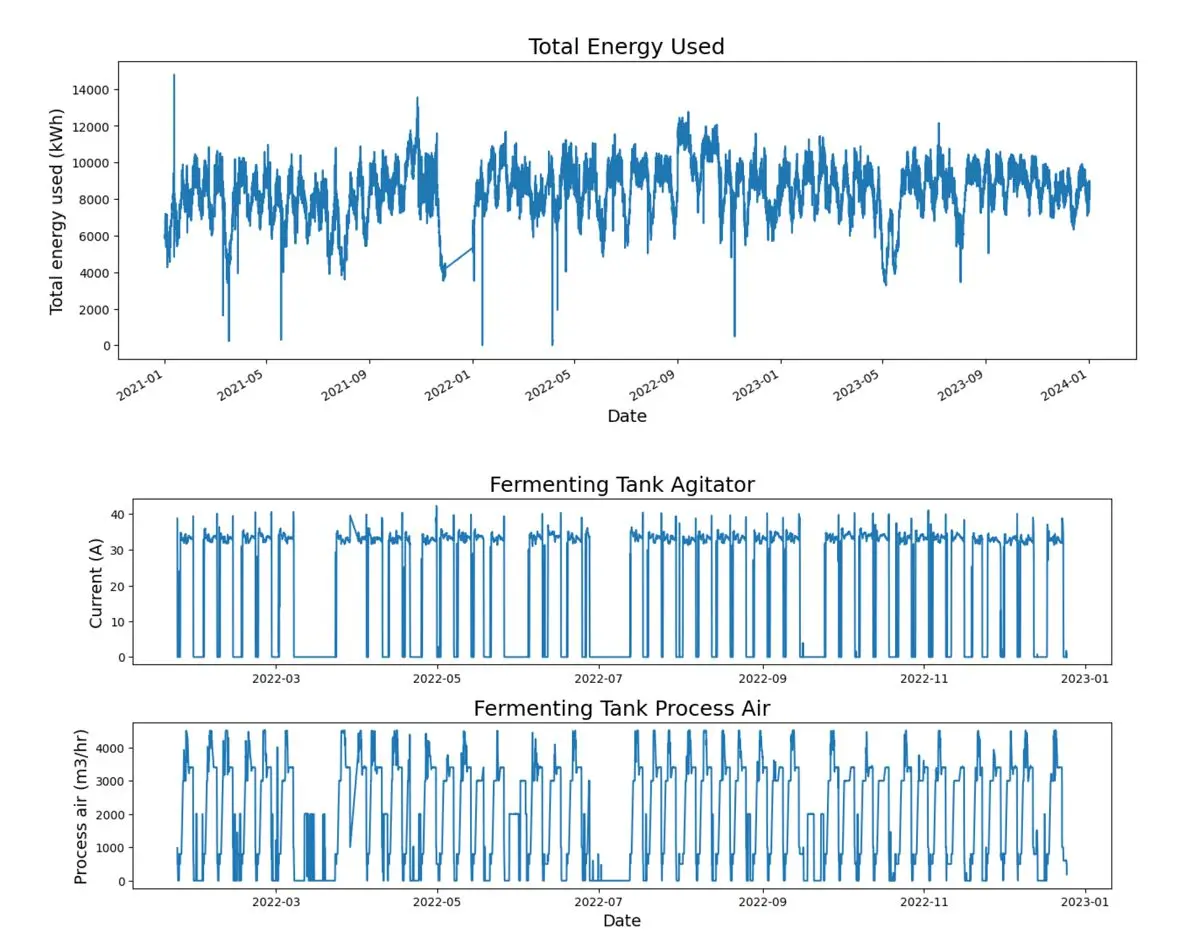

GSK’s Irvine site showed a strong correlation between batch production schedules and energy consumption, but fluctuations in machine usage made energy consumption forecasting difficult. GSK needed a robust decision-support tool to better understand the financial and environmental impact of its production planning decisions.

Solution:

GSK collaborated with Decision Lab to develop a hybrid model combining machine learning (ML) and simulation. This solution used predictive analytics in manufacturing to connect production planning with energy consumption forecasting, enabling smarter and more sustainable operations.

Results:

- Enhanced energy consumption forecasting.

- Optimized renewable energy sources.

- Optimized production plans.

- Reduced costs and emissions.

- Increased resilience to unexpected failures.

Introduction: sustainability goals in biopharma manufacturing

GSK's Irvine site

Decision Lab is a UK-based analytics and decision-support consultancy specializing in simulation modeling, artificial intelligence, and data science. With its expertise in predictive analytics in manufacturing, Decision Lab was able to implement a simulation model for GSK’s energy efficiency initiative.

GlaxoSmithKline (GSK) is a global biopharmaceutical company operating in over 130 countries, producing a wide range of products including vaccines, oncology drugs, and respiratory treatments. With more than 70,000 employees and 86 manufacturing sites, GSK generated £34 billion in revenue in 2023.

In line with its sustainability goals, GSK aims to achieve net-zero greenhouse gas emissions across its entire value chain by 2045. Key goals include sourcing 100% renewable electricity by 2025 and reducing absolute greenhouse gas emissions by 80% by 2030.

Problem: optimizing energy consumption

GSK’s Irvine site showed a strong correlation between batch production schedules and energy consumption, but fluctuations in machine usage made energy consumption forecasting difficult. The company needed a robust decision-support tool to better understand the financial and environmental impact of its production planning decisions. Specifically, GSK sought to:

- Establish a clear relationship between production schedules and energy consumption.

- Explore the feasibility of integrating additional renewable energy sources into its infrastructure.

- Optimize production plans to reduce overall energy costs and environmental impact.

- Simulate the effects of potential system failures and unforeseen operational disruptions.

- Analyze machine usage patterns to identify inefficiencies and reduce energy waste.

Solution: predictive analytics with machine learning and AnyLogic

To address these challenges, GSK collaborated with Decision Lab to develop a hybrid model combining machine learning (ML) and simulation. This solution used predictive analytics in manufacturing to connect production planning with energy consumption forecasting, enabling smarter and more sustainable operations.

ML model:

- Baseline analysis: A Python-based model analyzed historical energy data to establish a baseline for consumption under fixed production plans.

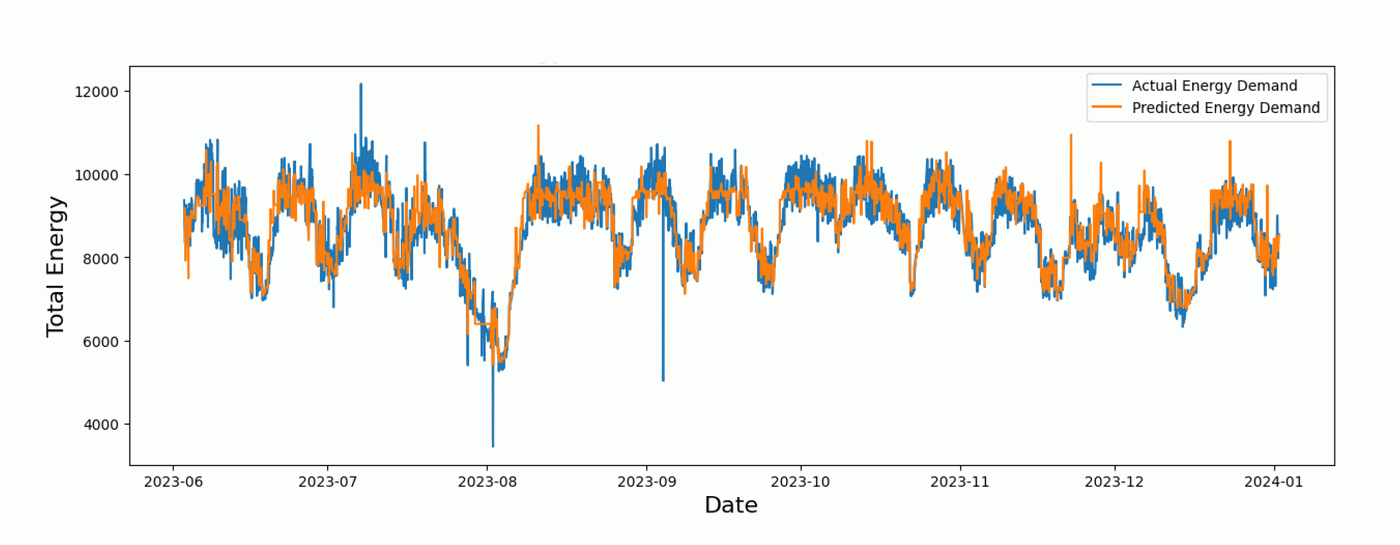

- Energy consumption forecasting: A Random Forest Regressor predicted electricity and steam usage based on machine schedules, improving the precision of energy forecasts.

actual demand and predicted consumption graph (click to enlarge)

AnyLogic simulation model:

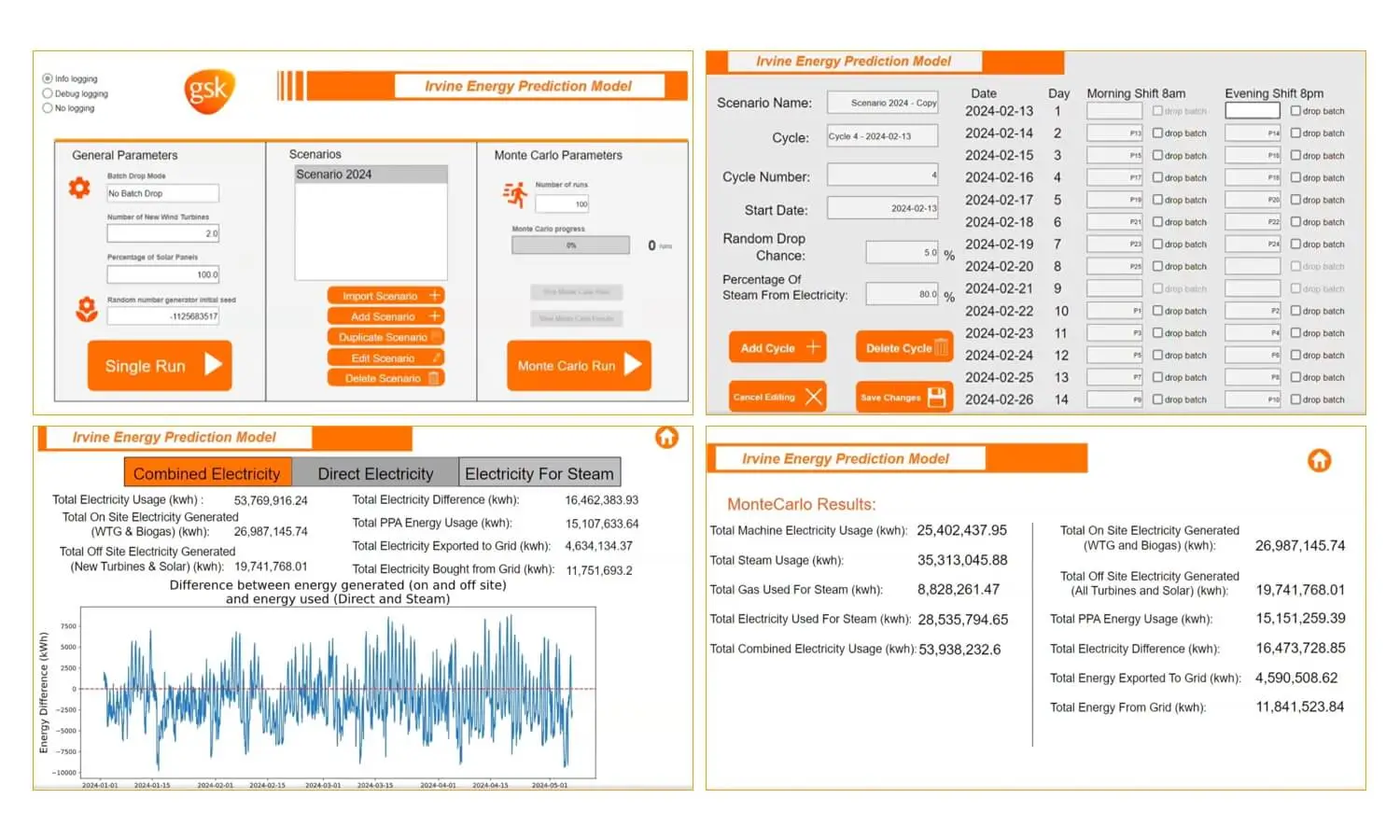

- Integration with AnyLogic: Outputs from the ML model were integrated into AnyLogic to assess the impact of adding renewable energy sources, such as wind and solar, into the site's operations. The simulation built a link between the cycle plan and energy usage in real-time.

- Scenario testing: The model was allowed to run “what-if” simulations of alternative manufacturing plans and unexpected failure scenarios, using Monte Carlo simulations to account for variability and uncertainty.

- Machine usage and energy consumption: The model tracked machine utilization and energy consumption, identified inefficiencies, and suggested improvements for energy reduction.

- Detailed energy tracking: The model included variables such as electricity, steam, gas usage, and energy generation from renewable sources to provide a holistic view of energy consumption.

Why AnyLogic?

GSK and Decision Lab selected AnyLogic for its advanced capabilities in predictive analytics in manufacturing and simulation modeling. Seamless Python integration via Pypeline enabled real-time data exchange between the machine learning forecasts and the simulation model, supporting dynamic and accurate modeling.

AnyLogic’s advanced analytics offered multiple run modes, Monte Carlo experiments, and KPI tracking to offer deeper insights into energy efficiency optimization.

Additionally, AnyLogic’s user-friendly interface, including a detailed data editor and visualization tools, enabled both technical and non-technical users to explore and interpret scenarios effectively.

Results: strategic advantages for GSK

The predictive analytics in the manufacturing approach provided GSK with substantial strategic advantages:

- Accurate energy baseline: The model created a detailed benchmark for current energy use, enabling more precise tracking and future forecasting.

- Renewable energy optimization: Simulated solar/wind energy integration helped GSK plan investments efficiently.

- Optimized production plans: With more accurate energy consumption forecasting, GSK adjusted production schedules to align with energy efficiency goals.

- Cost and emission reductions: The ability to evaluate renewable energy scenarios led to potential cost savings and emissions cuts.

- Operational resilience: The simulation allowed GSK to evaluate and prepare for unexpected failures, reducing downtime and energy waste.

- Enhanced forecasting capabilities: Predictive modeling helped GSK plan energy consumption more efficiently and minimize reliance on non-renewable sources.

By combining machine learning with AnyLogic simulation, GSK implemented a powerful solution for predictive analytics in manufacturing. The resulting decision-support tool enhanced energy consumption forecasting and optimization, aligning operations with GSK’s sustainability targets.

This successful case not only advances the company’s net-zero strategy but also provides a scalable model for other facilities seeking to improve operational efficiency and environmental performance.

The case study was presented by Joshua Liu and Jacob Whyte from Decision Lab and Giovanni Giorgio and Anjli Pankhania from GSK at the AnyLogic Conference 2024.

The slides are available as a PDF.