Problem:

KSE needed to address inefficiencies in designing and optimizing clients’ dosing and weighing systems in the animal nutrition industry. Complex container movement, varying dosing times, and unpredictable bottlenecks made manual manufacturing optimization impractical, increasing costs and limiting flexibility.

Solution:

KSE developed an AnyLogic simulation model to test different pet food production lines and system configurations. This allowed engineers to optimize throughput and improve decision-making before implementation.

Results:

- Factory design and validation timelines were reduced from weeks to hours.

- Inefficiencies were identified in the early stages of projects, resulting in significant savings in manufacturing optimization.

- 2D/3D visualization of simulation models improved client communication and sales effectiveness.

Introduction: pet food factories design and manufacturing optimization

KSE Group specializes in manufacturing dosing and weighing systems for the animal nutrition industry. With a history dating back to 1973, KSE provides solutions ranging from factory design and engineering to automation and aftercare optimization services.

Problem: animal nutrition production lines of different complexity

KSE faced several challenges while designing and optimizing their clients’ factories with dosing and weighing systems for animal nutrition production. The common complexities included:

- The movement of containers and dosing operations on pet food production lines involved numerous interdependent variables, including different process times, multiple routes, and potential bottlenecks.

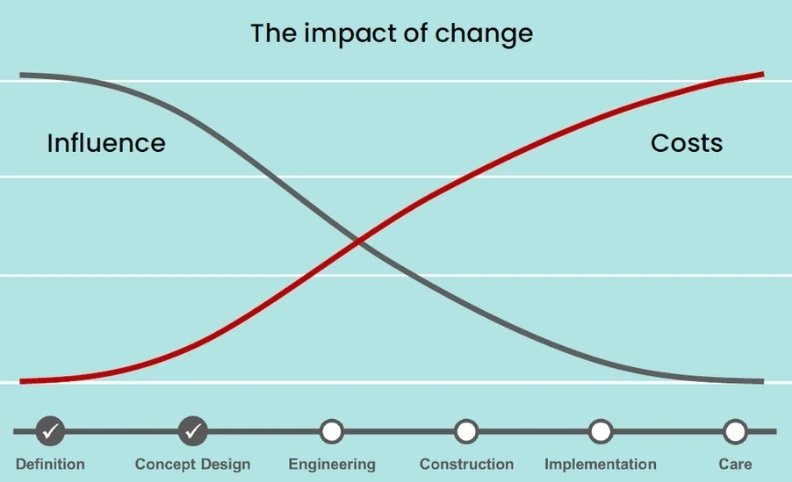

- Modifying factory layouts and processes after physical implementation resulted in significant cost and time spent on manufacturing optimization.

- Each factory had unique requirements, necessitating a flexible simulation tool to accommodate different layouts and operational constraints.

There was also a strong need for improved client communication. A visual and interactive representation of factory plans was required to effectively convey system performance and benefits. Therefore, sales consultants needed to configure factory layouts dynamically without requiring extensive simulation expertise.

Solution: simulation modeling for manufacturing optimization

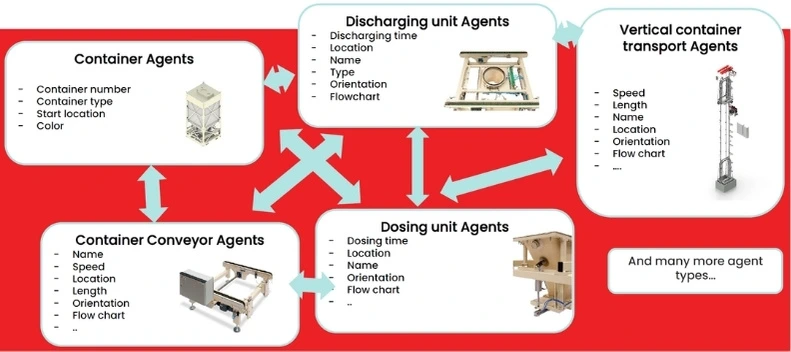

To address these challenges, KSE adopted AnyLogic. Using an agent-based simulation modeling approach, they created a simulation model in which each Automated Container Transfer (ACT) system’s unit type, such as elevators, conveyors, and dosing units, was represented as an agent.

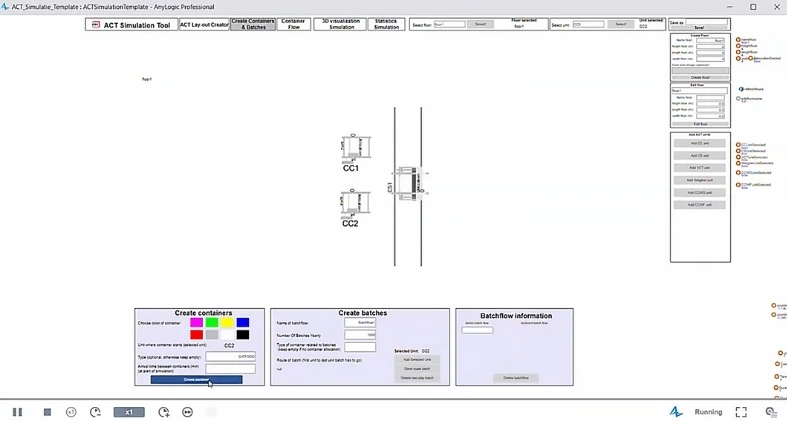

The model served as a base for multiple configurations and pet food production line analysis. Running the model and defining the factory floor layout, the number of containers, and the flow didn’t require special technical skills. This made the simulation model a powerful visualization and sales tool, offering clear insights into container movements and process flows. This improved internal decision-making while boosting customer engagement.

Results: efficient design and implementation of pet food production lines

Implementing AnyLogic to simulate dosing and weighing systems brought significant benefits to KSE. The time required to design and validate factory setups was reduced from weeks to hours. Additionally, early detection of potential issues enabled cost-effective adjustments prior to physical implementation, saving time and resources.

The interactive simulation tool improved client communication, ensuring their expectations were met before finalizing factory designs.

The company is not stopping there. It is working on integrating artificial intelligence tools into the simulation models to refine performance predictions and manufacturing optimization. Additionally, KSE is working on creating digital twins—real-time, data-driven replicas of physical production systems—to enable predictive maintenance and dynamic production planning.

Read also our blog post about simulation modeling trends in 2025, including the usage of artificial intelligence in simulation modeling and the next level of digital twins with real-time data streaming.

The case study was presented by Aron den Teuling from KSE Group at the AnyLogic Conference 2024.

The slides are available as a PDF.