Problem:

Sogrape required a new, flexible production facility to eliminate inefficiencies, overcome bottlenecks, and support future growth amid changing product demands.

Solution:

LTPlabs developed four optimized facility layouts and tested them using an AnyLogic simulation model to identify the most efficient configuration.

Results:

Simulation helped prove the concept of need in a new production facility design.

- 30% increase in production throughput.

- 25% reduction in lead times.

- 20% improvement in resource utilization.

Introduction: FMCG production

Sogrape products

The FMCG sector demands constant innovation and efficiency to stay competitive. In the beverage industry, balancing tradition with modern FMCG production needs is crucial.

Sogrape, a leading wine producer from Portugal, sought to meet rising market demands while maintaining its reputation for quality. To achieve this, they required a new design for their production facility in Avintes, Porto.

Partnering with LTPlabs, a consulting firm that blends advanced analytics and AI expertise, Sogrape embarked on a transformative project for a new production facility design.

Problem: under-utilization of the existing production facility

Sogrape wine company, a prominent FMCG producer, faced significant inefficiencies in their existing production processes. Bottlenecks in the current facility layout limited production throughput, increased lead times, and reduced resource utilization. The lack of flexibility hindered the company's ability to adapt to changes in product demand. Therefore, Sogrape needed a new production facility that could not only meet current operational requirements but also accommodate future growth.

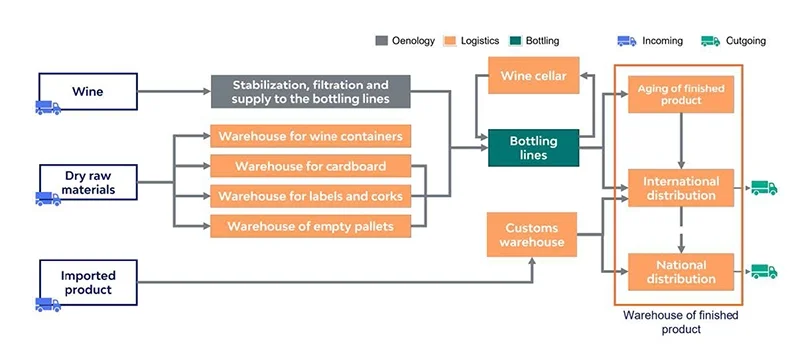

Solution: facility layout development

To address the challenges, LTPlabs took a comprehensive approach. They began by studying the Sogrape operations, gaining a deep understanding of the FMCG production processes, and pinpointing the bottlenecks that were causing inefficiencies. This initial step laid the basis for developing a tailored facility layout.

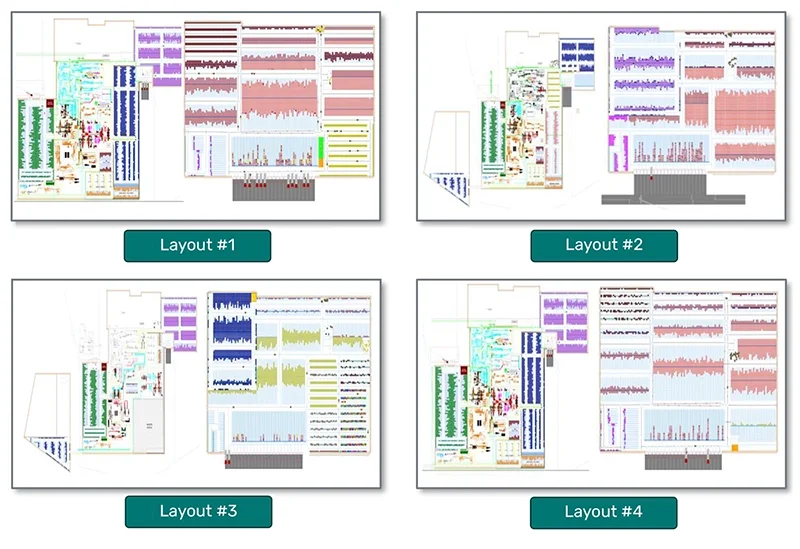

The LTP experts developed four facility layouts, suggesting different approaches for solving the challenge. They designed four layouts, which you can see in the picture below.

Each facility layout had a unique configuration:

- Layout #1: Raw material and semi-finished storage on the upper floor; finished product storage and shipping on the lower floor.

- Layout #2: Finished product storage and shipping on both floors; raw material reception on the upper floor with storage on both levels; semi-finished storage on the lower floor.

- Layout #3: Finished products stored in a vertical warehouse and on the lower floor; shipping and production lines on the lower floor; raw material reception on the upper floor with storage on both levels.

- Layout #4: Similar to Layout #1, but with partial outsourcing.

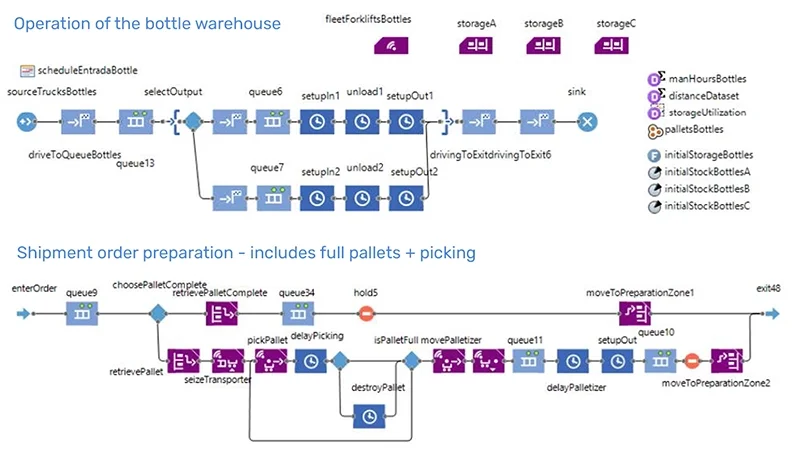

After they agreed on four layout options, LTP moved to the next phase—building a simulation model. This served as a virtual replica of the FMCG production environment. The AnyLogic model provided LTPlabs with a detailed view of operations within the facility without disrupting ongoing operations.

Several key AnyLogic features were extensively used in this project:

- With different storage systems and transporter fleets, LTP easily modeled facility storage systems and assigned the precise number of forklifts required for each area.

- Agent-based simulation allowed LTP to define unique characteristics for different floors and adjust scenarios across various layouts.

- Java integration enabled greater flexibility in accurately depicting real-world processes.

- Variables, data sets, and events helped to collect and track KPIs.

The AnyLogic model gave LTP a clear view of the pros and cons of the designs of each facility layout. They tested how they would work over a day, month, and year, helping them predict the results.

In addition, LTP looked beyond the facility layout and explored automation options. By reviewing Sogrape's budget and goals, they found ways to simplify processes, reduce manual work, and boost production speed and accuracy.

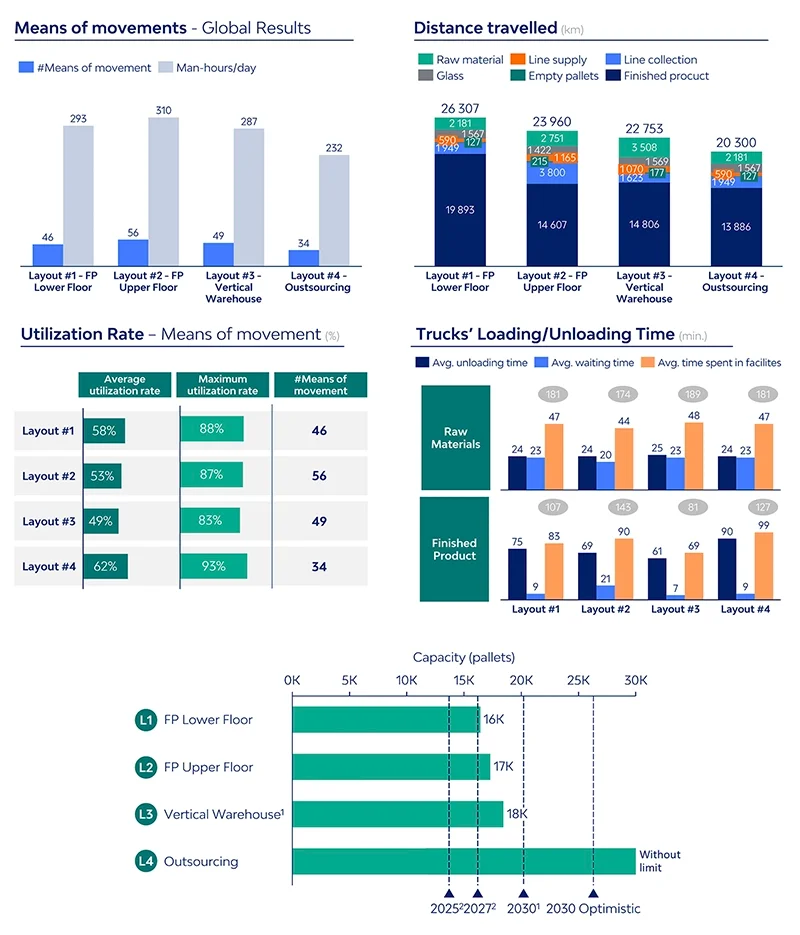

Results: an overview of the suggested new production facility layouts

Finishing the project, LTPlabs came up with the optimal design of the facility layout that combined smart analytics with practical design. The solution met Sogrape's current needs and supported future growth.

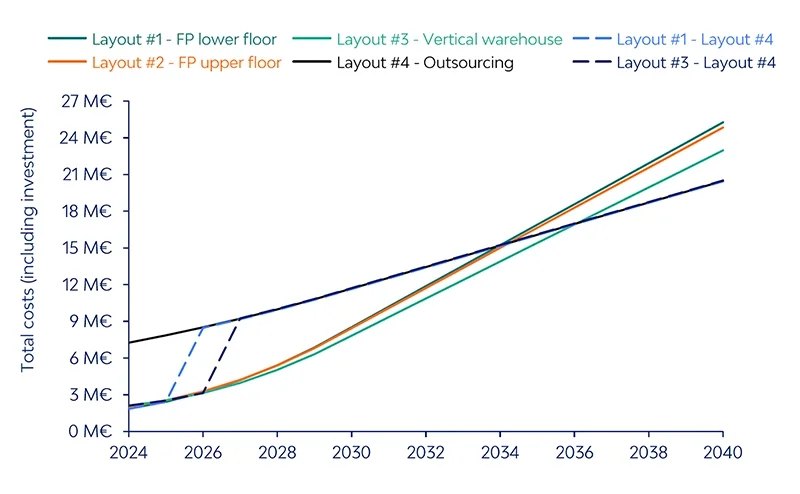

Based on the key metrics, LTP consultants made three conclusions:

- Layout #1 emerged as the most efficient configuration, requiring fewer person-hours per day compared to other layouts.

- Layout #1 and Layout #3 presented the least congestion.

- By 2030, Layouts #1, #2, and #3 would not have sufficient storage capacity, underscoring the importance of transitioning to Layout #4 with outsourcing.

The project delivered remarkable improvements across key performance metrics:

- 30% increase in FMCG production throughput: The new production facility would significantly boost the production capacity.

- 25% reduction in lead times: Streamlined processes would cut the time required to produce and deliver goods.

- 20% improvement in resource utilization: Optimized workflows ensured better use of equipment and workforce.

- Enhanced flexibility: The new production facility layout allowed for quicker adaptation to changes in FMCG product demand.

The simulation analysis gave Sogrape useful insights and a plan for the new design of the production facility. With LTPlab’s help, they made informed decisions to balance efficiency, growth, and costs.

The case study was presented by Inês Trovisco from LTPlabs and Filipe Ramalho from Sogrape at the AnyLogic Conference 2024. If you are interested in other LTPlabs projects, check out the Improving Customer Satisfaction at Checkout case study.

The slides are available as a PDF.