Black Friday was once a phrase used by Philadelphia police in the 1960s to describe traffic jams after Thanksgiving. Over time, retailers gave Black Friday a new meaning. It became the day when strong holiday sales could turn an unprofitable year into a profitable one.

In 2024, 197 million Americans shopped during Cyber Week, with $10.8 billion spent online on Black Friday alone. For many businesses, this marks the start of weeks that are filled with record sales and nonstop pressure.

Retailers know the excitement comes with real risks. Shelves can empty faster than they are restocked, supply chains face delays, and online platforms strain under traffic spikes. A single hiccup can turn into lost sales or disappointed customers.

The biggest challenge, particularly for Black Friday, is the demand side.

In this blog post, we’ll break down Cyber Week and show how simulation modeling supports retail optimization and strengthens retail demand forecasting. With this approach, businesses can prepare for demand spikes, test strategies, and avoid costly disruptions during the busiest season of the year.

Contents:

- Two-month marathon of sales

- Seasonal retail challenges

- Why traditional planning falls short

- Retail optimization with simulation

- How simulation powers retail optimization

- Benefits of simulation in retail

- Case studies: simulation in action

- Beyond Black Friday

- How to get started

Two-month marathon of holiday sales

Retail has its own fifth season—the season of sales. It kicks off in November with Thanksgiving and Black Friday, then rolls straight into December without a pause. Cyber Week is where it all begins.

Understanding Cyber Week

Cyber Week refers to the five-day period starting on Thanksgiving Day and ending on Cyber Monday. Once thought of as individual shopping events, these days now form a continuous sales cycle that sets the pace for the holiday season.

For retailers, this period highlights the importance of retail optimization to manage inventory, logistics, and the customer experience. At the same time, retail demand forecasting becomes essential for anticipating sudden surges in traffic and sales.

Thanksgiving Day

In 2024, more than half of U.S. consumers reported making at least one purchase before Black Friday. Once reserved for family gatherings, Thanksgiving has become the unofficial start of holiday deals. Many retailers now launch promotions ahead of Black Friday itself, capturing shoppers who want to avoid the rush.

Black Friday

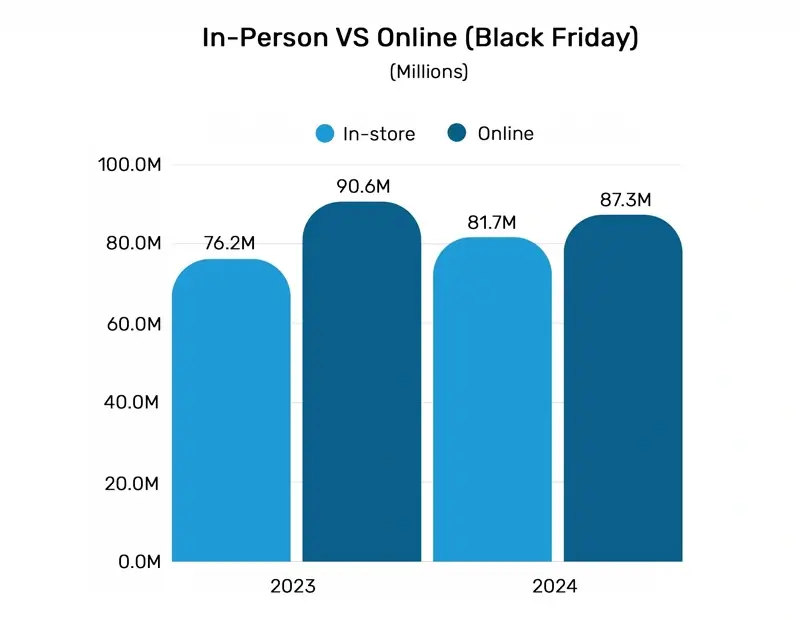

Still the single biggest day for in-store traffic, Black Friday has also grown into an online powerhouse. In 2024, 87.3 million Americans shopped online and 81.7 million shopped in-store, a sign of just how balanced the day has become.

Small Business Saturday and Sunday sales

The weekend between Black Friday and Cyber Monday has taken on new importance. Small Business Saturday encourages shoppers to support local businesses, while Sunday has become a bridge day, with retailers extending deals to spread out demand before Monday’s rush.

Cyber Monday

Now the biggest e-commerce day of the year, Cyber Monday 2024 saw $13.3 billion in online sales in the U.S. Electronics, toys, and apparel dominate the category mix. At the same time, mobile shopping continues to grow, with more than half of purchases now made on phones.

In this context, retail demand forecasting is critical for predicting which categories will surge, while effective optimization helps retailers keep sites fast, inventories balanced, and deliveries on time.

But the sales don’t stop there…

Cyber Week may mark the official start of the holiday shopping season, but December is when the real test for retail processes begins. Sales remain strong through Christmas Eve as shoppers hunt for last-minute gifts and seasonal promotions. In 2023, U.S. holiday retail sales for November and December hit a record $964.4 billion, according to the National Retail Federation.

Last-minute shopping continues to grow rapidly. Mastercard data shows that the last five days before Christmas accounted for 10% of all U.S. holiday spending in 2024.

And even after December 25, the season isn’t over. Post-holiday sales and gift card redemptions drive another surge in demand, alongside a flood of returns that can account for around 15% of all holiday purchases and nearly 18% of e-commerce sales. Both retail demand forecasting and retail optimization remain critical here, helping businesses prepare for returns while maximizing post-holiday opportunities.

Seasonal retail challenges: importance of retail demand forecasting

The holiday season is marked by fluctuating demand, changing shopper behavior, and nonstop operational pressure. Each stage of the season brings its own challenges, and together they create a mix that can be hard to manage.

Here are some of the challenges retailers most often face during the holidays:

- Unpredictable demand Sales can swing suddenly. A product that sells out online in one market might barely move in another, leaving planners scrambling. Strong retail demand forecasting is essential to anticipate these shifts and prevent costly missteps.

- Inventory balance Too little stock means empty shelves and lost revenue. Too much stock ties up cash and often forces heavy markdowns in January. Smart retail optimization helps strike the right balance between availability and profitability.

- Supply chain pressure Ports, shipping networks, and distribution centers all run close to capacity. Even a small disruption can cause delays that hurt customer trust.

- Staffing needs Seasonal workers are essential, but hiring and scheduling at the right scale is difficult. Gaps in staffing quickly show up in slower fulfillment or longer queues. Retail optimization helps allocate resources efficiently to meet spikes without overspending.

- Customer expectations Shoppers want fast delivery, simple returns, and a smooth in-store experience. A single poor interaction is often enough to push them to a competitor.

These challenges are not new, but the holiday season magnifies them. What might be a minor issue in July can become a major setback in December. This is why retailers need more than basic forecasts; they need ways to test strategies and prepare for uncertainty before it arrives.

Why traditional planning falls short

The holiday season is unpredictable. A viral trend, sudden weather, or a global shipping delay can throw off even the best forecasts. Traditional planning methods, often built on static spreadsheets, can’t keep up with that level of volatility, which is why strong retail demand forecasting is essential to stay ahead.

Read also: Discover how predictive modeling and simulation combine with AI to create smarter and adaptive systems.

Retailers often fall back on quick fixes, but each comes with trade-offs:

- Overstocking → ties up capital and leads to markdowns in January.

- Understaffing → results in longer queues and higher customer dissatisfaction.

- Rigid systems → offer little flexibility when demand shifts.

- Siloed planning → means online, in-store, and supply chain decisions don’t align.

Modern retail adds even more complexity: customers mix online, pickup, and in-store shopping, and they expect everything to work seamlessly. A small disruption in one area, like late shipments, quickly ripples through the rest.

That’s why retailers need more than a single forecast. They need ways to test different scenarios, prepare for uncertainty, and apply retail optimization strategies to build resilience before the season begins.

Retail optimization with simulation modeling

Instead of guessing or relying only on historical data, retailers can use simulation modeling to test strategies in a virtual environment before putting them into action. Think of it as creating a “digital rehearsal” for Black Friday or for the entire sales season.

What is simulation modeling?

Simulation modeling is the process of creating a virtual representation of real-world systems, such as stores, warehouses, or supply chains. It shows how these systems perform in different situations. Retailers can use it to test decisions in a risk-free environment and uncover insights that traditional forecasting tools can’t provide.

With simulation, businesses can:

- Stress-test operations under different demand levels.

- Experiment safely with promotions, staffing, or delivery options.

- Observe ripple effects when one part of the system changes.

- Plan for uncertainty instead of a single “best-guess” forecast.

This is where AnyLogic software stands out. Unlike other tools, it supports multiple methods within a single platform:

- Discrete-event simulation → model processes like checkout lines or warehouse flows.

- Agent-based modeling → capture customer behavior, staff decisions, and shopper interactions.

- System dynamics → study big-picture trends such as demand surges or inventory cycles.

Retail is a mix of dynamic systems, human behavior, and complex logistics, and no single method is enough. By combining these approaches, simulation modeling gives retailers a full picture of how their business will perform when the stakes are highest, making it a powerful tool for retail optimization.

How simulation powers retail optimization

Simulation lets retailers test strategies in a safe, virtual environment before the holiday rush. It connects supply chains, stores, and customer behavior into a single system, showing how decisions ripple across the business.

Inventory & supply chain management

Getting stock levels right is critical. With simulation, retailers can balance inventory across regions, anticipate logistics delays, and reduce the bullwhip effect during demand spikes. These insights directly support retail demand forecasting, ensuring inventory decisions are data-driven.

- Allocate stock before and during promotions.

- Test supplier lead times and shipping capacity.

Read also: Explore how Infineon used simulation to analyze demand volatility and reduce the bullwhip effect during the COVID-19 semiconductor shortage.

Store operations & staffing

On Black Friday, customer flow and staffing face the most pressure. Retailers often use simulation to explore queues, store layouts, and staff schedules, enabling them to serve more shoppers with fewer disruptions.

- Optimize seasonal schedules for peak hours.

- Test store layouts virtually before rollout.

Omnichannel fulfillment

Shoppers expect smooth transitions between online and in-store experiences. One way to do this is by using simulation to check inventory and delivery capacity.

- Balance e-commerce, click-and-collect, and store stock.

- Model last-mile delivery under heavy loads.

Promotions & demand forecasting

Promotions drive sales but also create uncertainty. Retailers can test “what-if” campaigns and see how different customer segments respond.

- Forecast demand shifts from discounts or bundles.

- Prepare for early vs. last-minute shoppers.

Returns management

Returns after Christmas can overwhelm operations. Retail optimization means turning that flood into a predictable flow by improving warehouse and logistics capacity.

- Estimate return volumes.

- Avoid bottlenecks in reverse logistics.

By covering these areas, retailers move from reactive fixes to proactive planning—making the entire season more resilient and profitable with smarter retail demand forecasting.

Looking for ways to optimize your warehouse operations? Check out our detailed blog post on improving warehouse efficiency with simulation modeling to see real-world case studies and strategies in action.

Benefits of simulation in retail

Simulation helps retailers make better decisions under uncertainty by testing multiple scenarios before peak season. It reduces costs by optimizing inventory, labor, and logistics, avoiding both shortages and waste.

Customers also benefit directly, with shorter lines, faster deliveries, and reliable product availability. In the long run, simulation gives retailers an edge by helping them adapt quickly to disruptions and shifting consumer behavior, while also improving retail demand forecasting for future seasons.

Retail optimization success stories with simulation

The real value of simulation is best seen in practice. Leading retailers and logistics companies use AnyLogic to prepare for peak seasons, uncover hidden bottlenecks, and make smarter decisions before problems arise.

Amazon – keeping deliveries flowing during peak season

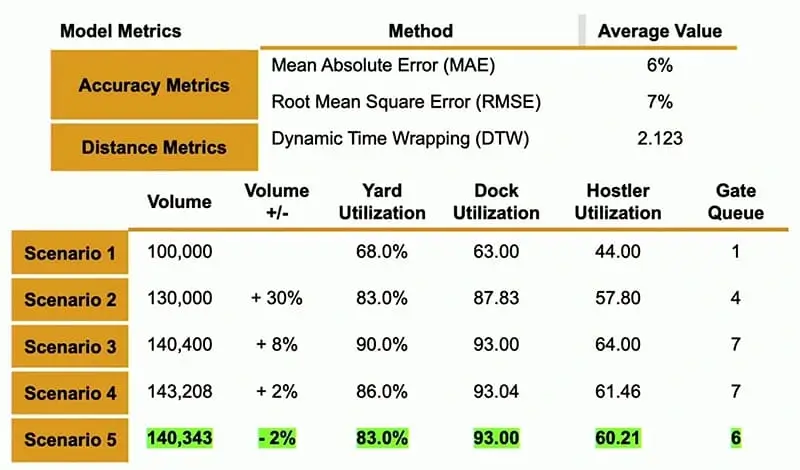

Black Friday and Christmas had pushed Amazon’s network to its limits. Fulfillment center yards faced gridlock: long truck queues, overloaded docks, and delays that threatened on-time deliveries.

Using an AnyLogic simulation model, Amazon tested more than 140 scheduling scenarios to see how traffic, dock use, and safety issues might unfold. The model flagged 95% dock utilization as a tipping point, predicted gate queues, and visualized blocked routes before they became real problems.

Simulation model of Amazon’s truck yard

The impact was immediate: costly on-site experiments were avoided, schedules could be tested virtually, and local teams gained a tool to validate new capacity plans with a single click.

With simulation, Amazon transformed peak-season chaos into a manageable system, ensuring millions of holiday orders arrived on time and enhancing its overall retail demand forecasting capabilities.

Read more in the case study of Amazon →

Note: This case was later highlighted in Gartner’s 2025 research on hyper-synthetic data, where AnyLogic was recognized as an innovator in hyper-synthetic data capabilities for process simulation and modeling platforms.

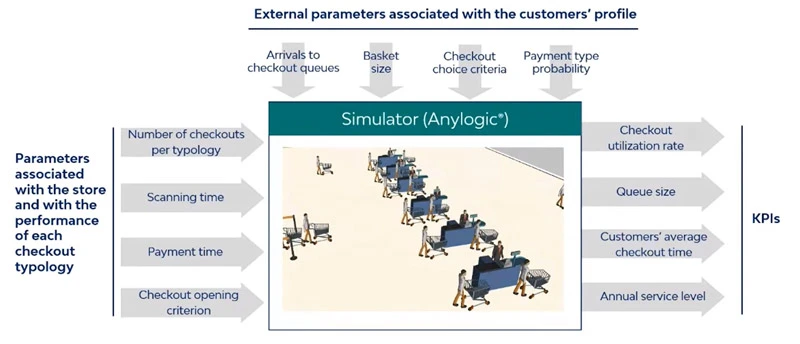

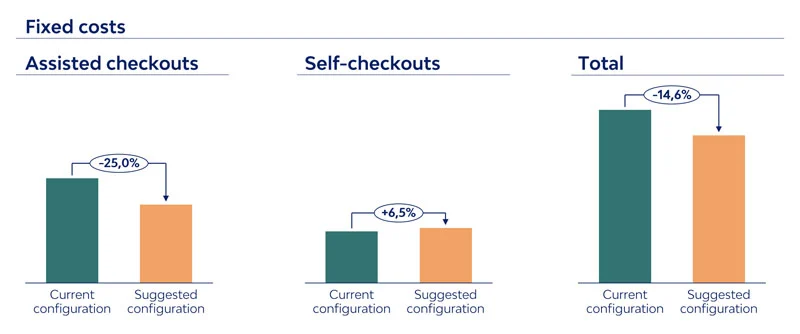

Sonae MC – optimizing checkouts ahead of holiday rush

During the hectic Black Friday and Christmas season, long queues at checkout areas pose a major risk to customer satisfaction and, ultimately, revenue. Sonae MC, Portugal’s leading food retailer, operating more than 1,300 stores, partnered with LTP to find the right balance between checkout availability and cost-efficiency across malls, supermarkets, and convenience locations.

Using AnyLogic’s multimethod simulation, LTP modeled different checkout configurations to determine which setups kept queues short, service fast, and costs low. The results were clear: by shifting a portion of customers to self-checkouts, stores reduced fixed costs by ~15%, cut operating expenses by ~12%, and improved overall checkout flow and customer experience.

Learn more in the case study of Sonae MC →

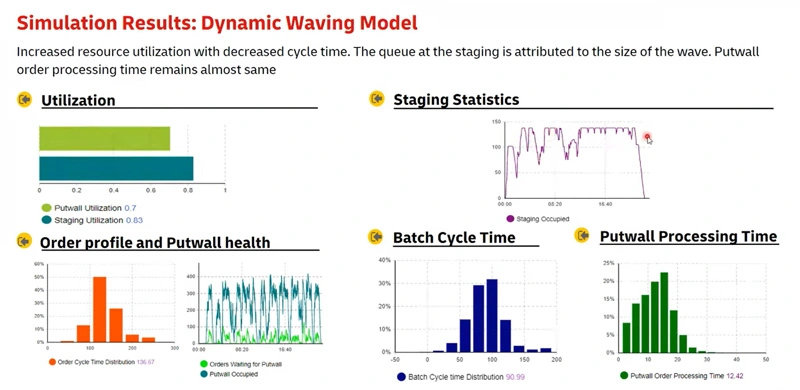

DHL – managing e-commerce warehouses at holiday scale

Global e-commerce grew by 320% in five years, leaving DHL Supply Chain struggling to balance service levels and costs. With hundreds of thousands of SKUs and complex order flows, traditional picking methods were no longer sustainable.

Using an AnyLogic simulation model, DHL tested dynamic wave-picking strategies to streamline operations. The results: order times fell by 8.2%, resource utilization increased by 10%, and 66 fewer staff were required. These efficiencies are crucial during Black Friday and Christmas, when warehouses face their heaviest loads.

Find out more in the case study of DHL →

Lojas Renner – tackling the last-mile crunch

For fashion and lifestyle giant Lojas Renner, Black Friday and Christmas bring an explosion of online orders. The challenge wasn’t just in distribution centers but also in the last mile, where high courier costs, slow lead times, and weak tracking threatened to disappoint customers.

Using AnyLogic, Renner tested new delivery models, including using stores as transit hubs, reallocating couriers, and solving complex routing problems. The model revealed bottlenecks, such as courier shortages at certain depots, and provided strategies to fix them.

The result: faster, more cost-efficient deliveries and a more reliable omnichannel experience during the most demanding shopping season of the year.

Find out more in the case study of Lojas Renner →

Beyond Black Friday: continuous improvement

Black Friday and Christmas put retail systems under maximum pressure. The insights don’t stop when the season ends. They support better decisions year-round through improved retail optimization and demand forecasting.

Simulation turns holiday lessons into everyday improvements. The same models that prevent checkout chaos in December can optimize staffing in spring or test new delivery options in summer.

As retailers move toward digital twins, simulation becomes part of an ongoing cycle of learning and adaptation. What once was a one-time stress test has become a tool for continuous growth and resilience.

How to get started

The Black Friday-to-holiday season will always be challenging, but with the right tools, it doesn’t have to be unpredictable. Here are a few practical ways to get started with simulation in AnyLogic.

Identify your pain points: Is your challenge checkout bottlenecks, last-mile delivery, or warehouse congestion? A focused model can deliver quick wins.

Explore case studies: Discover how companies like yours tackled similar problems and what worked for them.

Can’t find a relevant case study? Explore ready-to-run models online in AnyLogic Cloud. You can experiment with them yourself and even leave comments or questions.

Try AnyLogic today! The Personal Learning Edition is free and easy to start with. For advanced features, the Professional Edition offers more power—and our team is ready to help if you have questions.

And remember, with AnyLogic simulation, every Black Friday or holiday season is an opportunity, not a risk.